Cooling Efficiency for Effective Control:

Cost Optimization and Sustainable Solutions in the Food and Pharmaceutical Sectors

Cooling Efficiency for Effective Control:

Cost Optimization and Sustainable Solutions in the Food and Pharmaceutical Sectors

Cooling processes are critical in the food and pharmaceutical sectors to maintain product safety, freshness and effectiveness. However, the high energy consumption and costs associated with these processes significantly impact the operational efficiency of companies. Particularly, energy optimization during storage and distribution stages plays a crucial role in both financial savings and environmental sustainability. This study explores innovative solutions, such as solar energy integration, DC motor compressor technology and eutectic systems to overcome the limitations of traditional systems and reveal the transformation potential within the industry.

Key Factors in Cooling Costs: Storage and Distribution

Storage Costs

Cold storage facilities are among the major contributors to energy consumption. For example, the annual electricity consumption in a 10,000 m² warehouse can reach 1.5-2 million kWh (Jones & Lee, 2020). This consumption is directly related to factors such as:

- Ambient temperature fluctuations,

- Insulation quality,

- Frequency of door openings and personnel movement.

Increasing the thickness of insulation materials from 15 cm to 25 cm can reduce energy losses by 30-40% (Smith et al., 2021). It has also been observed that earthen constructions provide significant insulation effects.

Logistiscs Costs

In refrigerated transportation, energy and maintenance costs can account for up to 50% of total logistics expenses. On the other hand, especially in developing countries, inefficiencies in cold chain logistics result in 25% of food products spoiling before reaching consumers (FAO, 2022). With modern thermally insulated vehicles and dynamic temperature control systems, these losses can be reduced by up to 15%.

Solar Energy Integration: Cost and Environmental Benefits

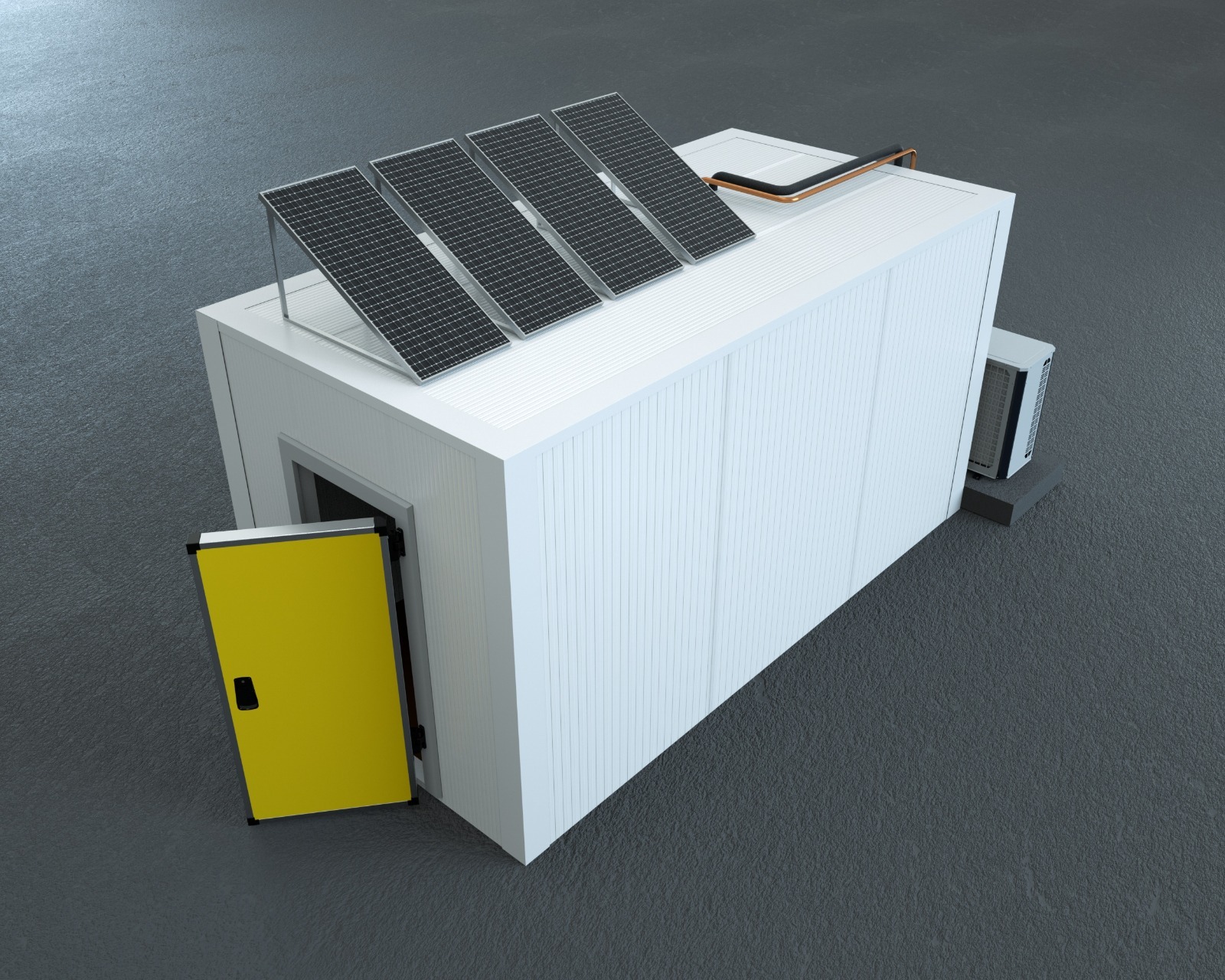

Solar energy reduces dependency on the grid in cooling systems, offering significant environmental and economic advantages. For example, a 20 ft container equipped with a 2.5-3 kW solar panel and a 10 kWh lithium-ion phosphate battery system can meet 8-10 hours of cooling needs without interruption. The main advantages of these systems are as follows:

- Zero Emission: A 1 MW solar energy system prevents the emission of approximately 1,500 tons of CO₂ per year (Wilson et al., 2021). This is considered a major step in reducing environmental impact.

- Cost Savings: By reducing grid electricity consumption by 70%, the system provides a return on investment in just 5 years. This offers substantial financial benefits in the long term, particularly for businesses with high energy costs.

- Energy Self-Sufficiency: In developing regions such as Africa, mobile cold storage units used for agricultural products have reduced regional food losses by 40% through solar energy (UNDP, 2023). This enhances energy self-sufficiency while also improving food security and logistical efficiency.

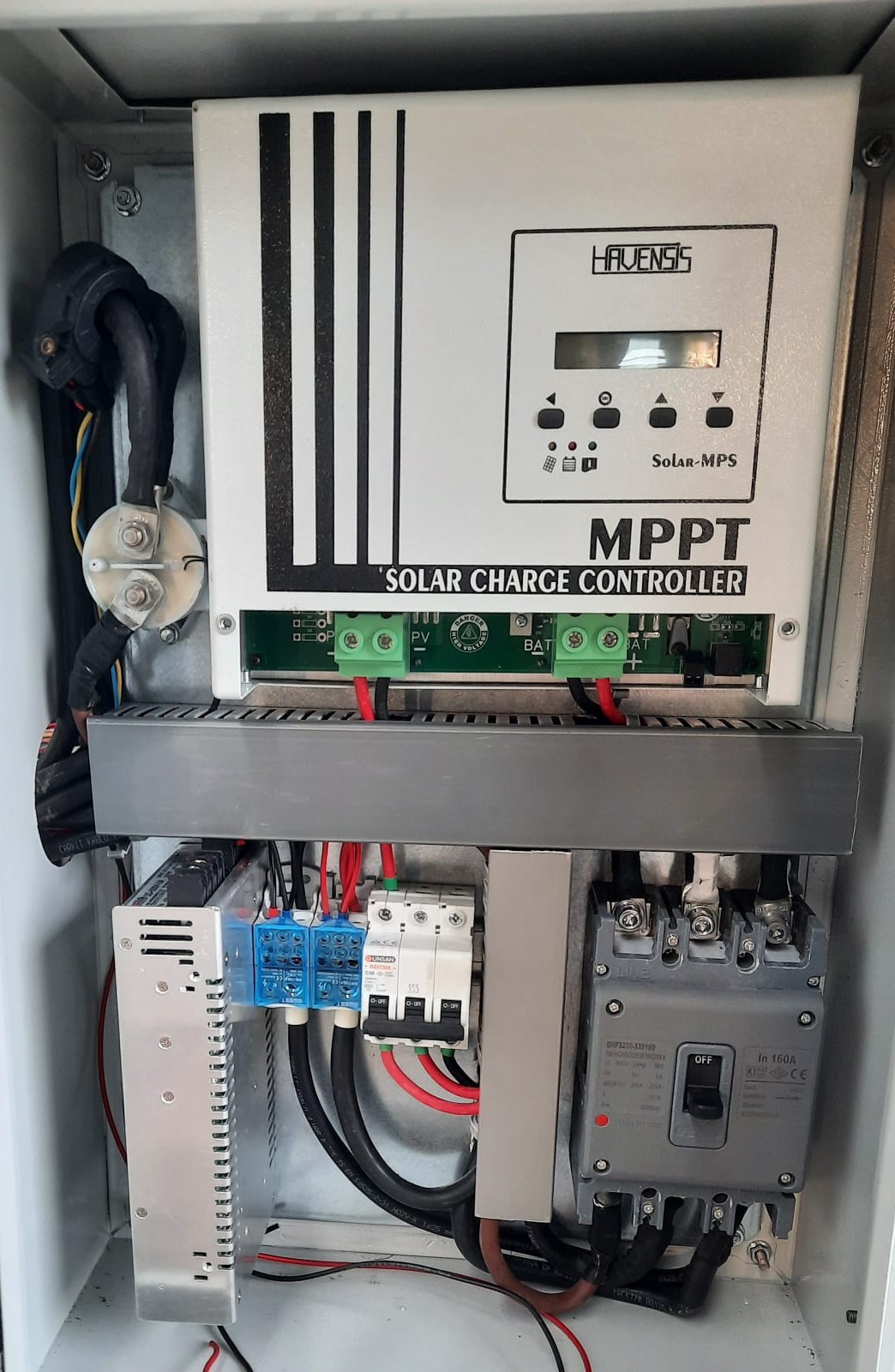

DC Motor Systems: Inverter-Free Efficiency

In traditional AC motor systems, energy losses due to inverters are between 15-30%. In contrast, DC motor compressors:

- Energy Efficiency: They consume 25% less energy by being directly powered by the battery.

- Smart Control: Compressor operation time is optimized with IoT-based speed adjustment. Energy consumption is almost zero when cooling is not required.

- Cost Advantage: The elimination of inverter costs reduces system installation by 10-15% (Garcia & Patel, 2022).

The DC motor system implemented by TURA Technology & Consulting in a joint project with ATC International provides a 37% energy advantage over the inverter-based system, along with more detailed control capabilities. On days with high UV Index, the energy from the solar panel was sufficient to meet the cooling needs of the container due to the cooling optimization effect.

Additionally, a pharmaceutical logistics company in Germany achieved annual energy savings of € 120,000 by switching to DC motor systems.

Eutectic Systems: Continuity with Energy Storage

Phase Change Materials (PCMs) offer significant advantages in thermal energy storage. For example, a PCM with a freezing point of -20°C can maintain temperature fluctuations within ±2°C for up to 12 hours. The advantages provided by these systems are as follows:

- Range Extension: Refrigerated trucks can extend their range up to 24 hours without additional energy requirements.

- Cost Optimization: PCMs reduce energy consumption by 35%, saving $50-70 per ton in cold chain logistics (Martinez & Chen, 2020).

The PCM-supported container project, executed by TURA Technology & Consulting with ATC International, utilized Phase Change Materials (PCMs) with a freezing point of -37°C for 3.5-meter vehicles and PCMs with a freezing point of -10°C for 7-meter vehicles. Testing these systems showed that, depending on the container size, the internal temperature remained within the desired range for 18 to 27 hours longer, without requiring additional energy consumption.

The Financial Impact of Cooling Optimization

Energy efficiency not only reduces operating costs but also lowers initial investment:

- Battery Cost: Efficiency improvement in a 20 kWh system reduces the battery capacity to 15 kWh, saving approximately $8,000.

- Remote Monitoring: Real-time tracking of temperature/humidity data through IoT sensors reduces product losses by 20% and guarantees compliance with ISO 22000:2018 standards.

Conclusion and Recommendations

Cooling efficiency in the food and pharmaceutical sectors can be optimized through the following technologies:

- Renewable Energy Integration

- Inverter-less DC Motors

- Eutectic PCM Solutions

These steps can reduce operational costs by up to 40%, while minimizing the carbon footprint. Government subsidy policies and industry R&D investments will expedite this transformation process.

References

Brown, J., Smith, K., & Lee, P. (2019). Cold Chain Logistics: Cost Analysis and Optimization. Logistics Journal.

Garcia, R., & Patel, M. (2022). Energy Efficient Refrigeration Systems. Energy Journal.

ISO 22000:2018. Food Safety Management Systems.

Jones, T., & Lee, C. (2020). Warehouse Cooling Efficiency. Industrial Cooling Review.

Martinez, F., & Chen, L. (2020). Eutectic Systems in Refrigeration. Journal of Thermal Science.

Wilson, G., et al. (2021). Solar-Powered Cold Storage: A Feasibility Study. Renewable Energy Journal.